Spherical Storage Tanks (commonly referred to as sphere tanks) are steel pressure vessels with a perfectly spherical shape, often compared to a giant soccer ball or watermelon. This design is widely used in petroleum refining, petrochemical processing, and liquefied product terminal storage, primarily for storing liquid or gaseous materials. Most sphere tanks feature a single-shell structure; however, when storing liquefied gases under low-temperature and low-pressure conditions, a double-shell configuration is adopted with insulating material placed between the two layers.

From a functional perspective, a spherical storage tank is a sealed pressure vessel designed for storage. The media it contains are often flammable, explosive, or toxic gases such as ethylene, pentane, liquefied petroleum gas (LPG), liquefied natural gas (LNG), propane, butane, natural gas, and butene. Due to the hazardous nature of these substances, the safety of sphere tanks has always been a major concern in industrial operations.

In terms of operating parameters, sphere storage tanks typically function within a temperature range of -50°C to 50°C, with operating pressure generally controlled below 3 MPa. Most sphere tanks currently used domestically are designed for temperatures between -40°C and 50°C, meeting the requirements of the majority of industrial applications.

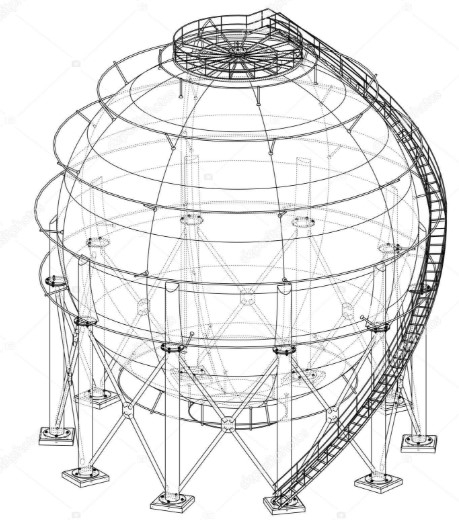

The ability of spherical tanks to operate safely in harsh industrial environments is largely attributed to their scientifically engineered structural design. Understanding their key components helps clarify both their working principles and maintenance requirements.

There are three primary structural configurations for spherical tanks, each with distinct characteristics:

- Ring-Belt Type (Orange-Peel Design): This is the most common configuration. The shell is divided into segments resembling orange peels, forming ring belts composed of multiple curved plates. Its advantages include simple weld arrangements, easy assembly, and relatively straightforward shell plate fabrication. The drawback is lower material utilization. Tanks with volumes below 1,000 m³ typically adopt this structure.

- Soccer-Ball Type: The shell segmentation mirrors the pattern of a soccer ball, with all plates identical in size—hence the name “equal division method.” Advantages include standardized cutting and forming, high material utilization, good interchangeability, shorter weld seams, and reduced welding and inspection workload. However, the weld layout is complex, assembly is challenging, and manufacturing precision requirements are high. Due to steel plate specifications and structural limitations, this design is generally suitable only for small tanks with capacities under 120 m³.

- Hybrid Type: This structure combines the strengths of both the orange-peel and soccer-ball designs. The equatorial and temperate zones use the orange-peel configuration, while the polar plates (top and bottom) adopt the soccer-ball pattern. Benefits include improved material utilization, shorter weld lengths, fewer shell plates, and strong suitability for large tanks. Today, most sphere tanks exceeding 1,000 m³ employ this hybrid structure.

Support columns are critical structural components that bear both the weight of the tank and the stored media. Several support forms are available:

- Column Supports: The most common type, using multiple vertical columns to hold the sphere.

- Skirt Supports: Similar to the skirt structure used in cylindrical vessels.

- Semi-Buried Supports: Partially embedded underground for enhanced stability.

- Elevated Supports: Raise the sphere above ground level.

Regarding material selection, ambient-temperature tanks typically use integral columns. Low-temperature tanks should adopt a two-section column design: the upper section, approximately one-third of the total length, is made from low-temperature-resistant steel, while the lower section uses standard structural steel. Proper alignment must be ensured at the connection between the two sections.

Additionally, column design must incorporate fireproof insulation measures, effective electrostatic grounding for each column, and pressure-relief provisions to vent expanding gases during a fire. Adjustable tie rods with sufficient strength should be installed between columns to withstand additional loads.

Sphere tank accessories encompass multiple functional subsystems:

- Operation and Maintenance Facilities: Ladders and platforms provide safe access for personnel and routine inspections. Manholes enable internal maintenance, tanks with volumes up to 1,000 m³ typically use a 500 mm nominal diameter manhole, while larger tanks use 600 mm units. Manholes should be positioned along the main axis of the upper and lower polar plates.

- Piping Interfaces: Nozzles are used for material inlet and outlet and should be constructed with thick-walled pipes. When the shell thickness is 30 mm or greater, manholes and other openings should employ an integrated reinforcement structure to maintain mechanical strength.

- Safety Monitoring Equipment: Level gauges monitor liquid height, pressure gauges track internal pressure, and thermometers measure temperature. All instruments require regular calibration.

- Fire Protection and Insulation Systems: Water spray devices provide cooling protection during fires, while thermal insulation or cryogenic protection systems help maintain media temperature and reduce energy loss.

While structural design determines performance potential, installation and welding directly affect whether that potential can be safely realized. Because sphere tanks typically store high-risk media, construction quality requirements are extremely stringent, any oversight can lead to severe consequences.

Several installation methods exist, including loose assembly, ring-by-ring assembly, hemispherical assembly, and large-section assembly. As tanks continue to increase in size, the hazards associated with assembly stress have gained greater recognition.

Currently, the equator-based loose assembly method is the most widely used due to the following advantages:

- Lower assembly stress, supporting long-term operational safety

- Simplified construction procedures for easier on-site work

- Reduced lifting capacity requirements

- Less crane usage, lowering construction costs

The sequence involves assembling the equatorial belt first, verifying alignment, and then installing the remaining belts. Although this method progresses more slowly, it offers superior quality control.

Welding is a critical stage in sphere tank construction and presents several challenges:

- High Workload: Tanks consist of numerous shell plates, resulting in substantial total weld length.

- Technical Difficulty: Welding positions include flat, vertical, overhead, and horizontal welds, all requiring strict technical standards.

- Multiple Processes: Manual shielded metal arc welding is commonly used on-site, supplemented by flux-cored semi-automatic welding and gas-shielded automatic welding to improve efficiency and quality.

- Heat Treatment: Preheating, post-weld heat treatment, and final overall heat treatment are necessary to eliminate welding stress and enhance material properties.

- Strict Inspection: Weld seams typically undergo 100% radiographic testing to ensure internal quality.

After completion, sphere tanks must undergo rigorous pressure testing:

- Hydrostatic Testing: This test verifies structural strength and evaluates assembly and welding quality, ensuring the tank can withstand design pressure without leakage. Overload hydrostatic testing can further enhance load-bearing capacity. Once the test is passed, magnetic particle or penetrant testing should be performed to detect surface cracks and defects.

- Gas Tightness Testing: Conducted after all accessories are installed and instruments such as pressure gauges, safety valves, and thermometers are calibrated. The test medium should be dry, clean air or another inert gas. This procedure represents the final safeguard for ensuring tank sealing integrity.

Compared with traditional cylindrical tanks, spherical tanks offer several notable advantages:

- Material Savings: A sphere has the smallest surface area for a given volume. Under identical capacity and pressure conditions, it requires the least amount of steel. The load-bearing capacity of a spherical shell is roughly twice that of a cylindrical vessel; with the same diameter and pressure, the required plate thickness is only half. Overall, steel savings typically range from 30% to 45%.

- Efficient Land Use: Sphere tanks occupy less ground area and can extend vertically, maximizing site utilization—especially valuable in land-constrained industrial zones.

- Lower Foundation Costs: Uniform stress distribution reduces foundation workload and associated expenses.

- Enhanced Safety: The spherical geometry ensures optimal stress distribution under internal pressure, minimizing stress concentration.

However, sphere tanks also have limitations. Manufacturing, welding, and assembly requirements are stringent, inspection workloads are high, and fabrication and installation costs are relatively expensive. Because stored media are hazardous, safety management standards must be exceptionally rigorous. Cold-pressed shell plates and challenging field welding conditions also demand advanced manufacturing and construction expertise.

Sphere tanks are generally categorized into three types based on operating temperature:

- Ambient-Temperature Sphere Tanks: Designed for temperatures above -20°C, commonly used to store LPG, nitrogen, coal gas, and oxygen. These tanks typically operate at higher pressures determined by the saturated vapor pressure of liquefied gases or compressor discharge pressure.

- Low-Temperature Sphere Tanks: Designed for temperatures at or below -20°C, typically not lower than -100°C, and suitable for media that must remain liquid under refrigerated conditions.

- Cryogenic Sphere Tanks: Designed for temperatures below -100°C, often storing media below their liquefaction points at relatively low pressure, sometimes even atmospheric. Due to extremely high insulation requirements, double-shell structures are frequently employed.

Several factors must be comprehensively evaluated in sphere tank design:

- Foundation Design: Ring foundations are recommended to effectively control differential settlement and prevent uneven stress on the sphere.

- Segmentation Strategy: Considering steel mill plate sizes, manufacturer press capacity, transportation constraints, and lifting capabilities, large shell plates should be used whenever possible. For medium and large enterprises, a hybrid segmentation combining soccer-ball and orange-peel patterns is recommended.

- Welding Requirements: T-shaped weld joints should be adopted. Spliced plates are not permitted, and support columns should never be positioned directly over butt welds to avoid stress concentration.

- Nozzle Reinforcement: Integrated reinforcement structures are necessary at openings when shell thickness is substantial.

Spherical storage tanks play an irreplaceable role in industries such as petroleum, chemicals, metallurgy, terminal storage, and urban gas supply. With the rapid development of the petrochemical sector and the growing demand for city gas, storage requirements for LPG, LNG, and other energy resources continue to rise, expanding the application scope of sphere tanks. Beyond traditional petrochemical uses, sphere tanks have also found applications in specialized fields such as the defense industry and paper manufacturing (e.g., digesters). Although their manufacturing costs are relatively high, a lifecycle perspective reveals that their advantages, material savings, reduced land usage, and lower maintenance costs, make spherical tanks the preferred solution for large-scale pressure storage vessels.