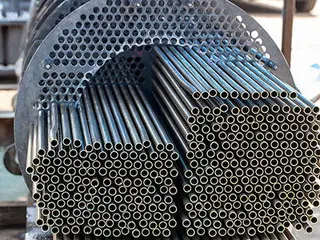

Storage Tank Design and Importance of Various Openings

Storage tanks are crucial for safely storing gases and liquids, and the design of internal openings plays a vital role in ensuring their storage function, ease of operation, and safety. Different types of openings not only fulfill specific functional needs but also guarantee the stability of the storage tank under high pressure and in special environments. This article will analyze the types, functions, design features, and practical importance of various openings in storage tanks. Probe Holes Probe...