The Vital Role of Surge Tanks in Oil Well Production

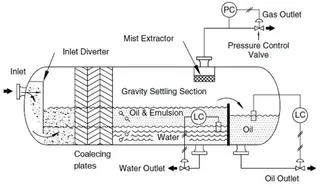

In today's petroleum industry, the stability and efficiency of oil well production systems are paramount. Surge tanks, as a key component, play a vital role in balancing system pressure and ensuring safe equipment operation. Their function is akin to the buffering effect of blood in the human circulatory system, capable of regulating internal pressure fluctuations to ensure the smooth operation of the entire production process. This article delves into the role, structure, and different...