Enhancing Heat Transfer in Heat Exchange Equipment: Common Methods

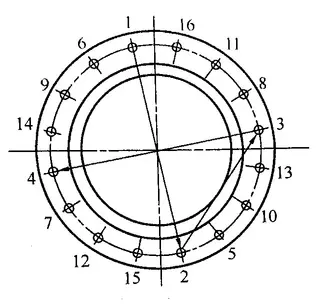

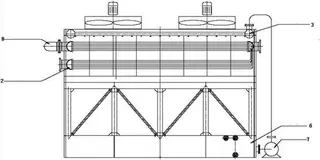

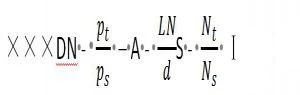

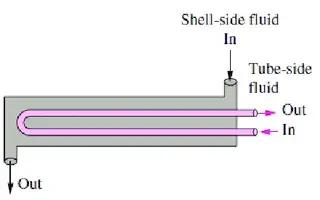

What methods can be employed to enhance heat transfer in heat exchanger equipment? One primary method is to increase the heat transfer surface area through various structural modifications: (1) Utilizing finned tubes, nailhead tubes, threaded tubes, spiral tubes, or bellows. (2) Machining the surface of the pipe with spiral grooves or threads. (3) Employing smaller diameter pipes to increase the number of pipes within the same tube plate area, thereby augmenting the heat transfer area. Another approach...